Your roofing contractor will discuss the most common roof attachments for single-ply commercial roofing projects: ballast, mechanically attached, and adhered. Here’s some quick information about each type.

Types of Roof Attachments for Your Roof System

It’s essential that you choose a roofing system and assembly that is compatible with your commercial building’s design and structure. Here are three standard attachment methods.

Ballasted Systems

Ballasted roof systems can be applied to many different types of buildings as long as the building structure and decking have been designed to hold the additional weight of the ballast. Here’s how a ballasted roof system generally works.

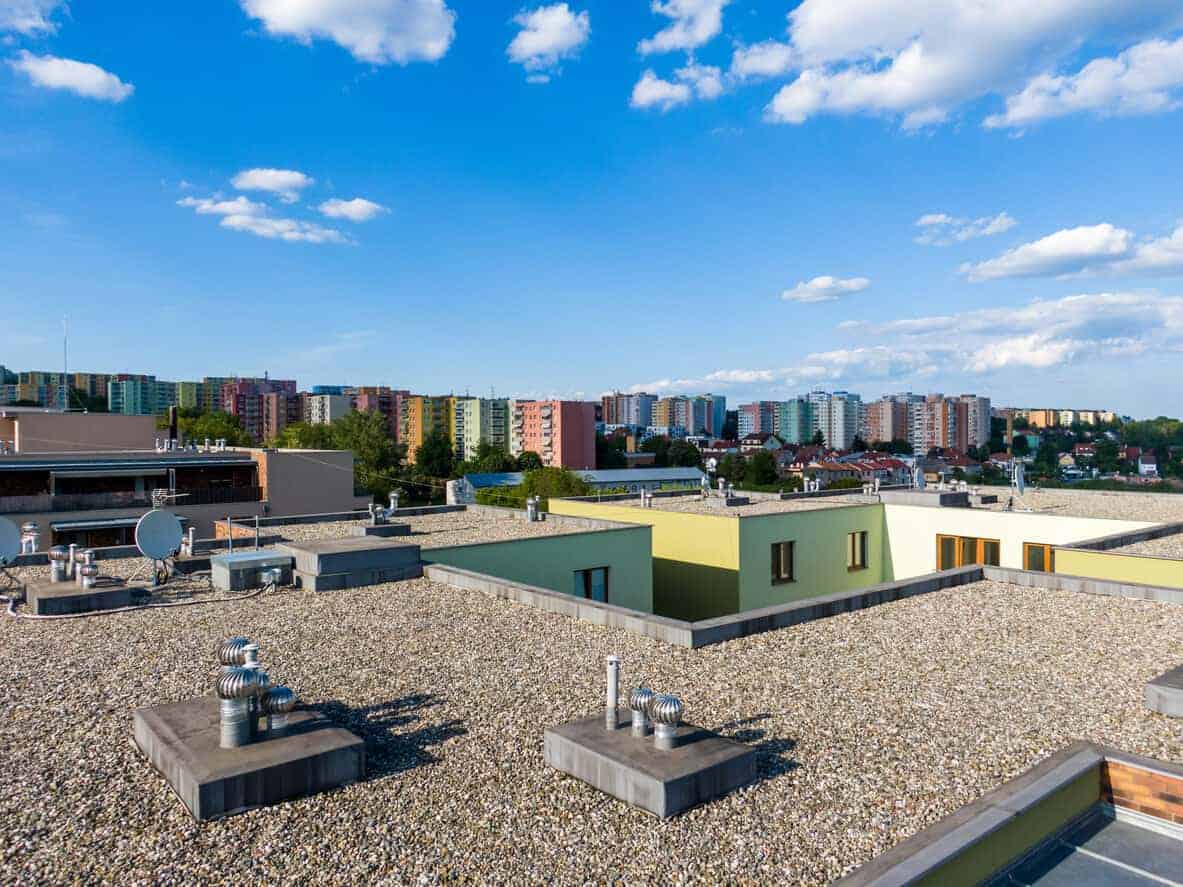

First, layers of loose insulation sheets are placed on top of the roof decking. Typically sheets of EPDM roof membrane follow this; the seams are fastened with seam tape. Then, all the perimeter and access points are sealed or flashed. Finally, loose laid washed river rock or pavers are applied to weigh down (at least 10 pounds per square foot) the insulation and EPDM roofing systems. Ballasted EPDM roofs are most commonly used on large open roofs without many penetrations, such as a warehouse.

A ballasted roof system has many benefits:

- Economical

- Fewer seams due to larger EPDM sheets

- Fast installation

- Excellent fire rating

- Offers resistance against weathering and hail damage

Mechanically Attached Systems

Unlike ballasted systems, mechanically fastened roofing systems do not add additional weight to a structure. This lightweight roof system can be applied if the roof decking provides enough pull-out resistance for the fasteners.

Here’s how mechanical attachment works:

Like a ballasted system, you start by placing insulation layers on the decking. These layers are securely fastened using insulation plates and other fastening hardware. Next, the layers of single-ply (EPDM, TPO or PVC) roof membrane sheets are placed over the insulation. Fasteners and plates secure the membrane and the insulation to the deck, most commonly placed inside the seams of overlapping membrane. EPDM systems use seam tape and TPO or PVC membranes are sealed by hot-air welding the seams together.

A mechanically attached system has many benefits:

- Secure

- Versatile

- Lightweight

Adhered Systems

An adhered roofing systems use adhesives to bond the membrane to suitable substrata, usually insulation, which have been mechanically attached to the deck. Adhered systems also can be applied to many different types of buildings, as long as the roof decking provides enough pull-out test resistance. Self-adhered membranes are also available.

Here’s how an adhered system works:

Sheets of insulation are laid on the roof system and then either adhered or mechanically fastened with foam adhesives or insulation plates and fasteners to the roof decking. Next, the membrane is laid out over the insulation, and bonding adhesive is applied to the underside of the membrane and the insulation. Adjoining sheets are overlapped and spliced together. Finally, the roof’s perimeter is sealed with flashing.

Here are the benefits of an adhered system:

- Strong

- Versatile

- Lightweight

- High wind uplift performance

Get Expert Advice from Nations Roof

Do you need commercial roofing system advice? The commercial roofing experts at Nations Roof will look at the technical specifications and determine which type of attachment system is right for your project. Nations Roof is one of the leading commercial roofing companies in the U.S. We provide a comprehensive range of commercial roofing services. Contact us today to discuss your commercial roofing project.