Comprehensive Services

Commercial Roofing Systems

We provide a comprehensive range of commercial roofing services to suit your needs and budget in a timely manner.

Welcome to Nations Roof®

At Nations Roof® our goal is to extend the life of your commercial roofs, minimize your investment in new roof maintenance, and remove unnecessary costs at every stage of its life cycle. We offer national coverage backed by great service—no project is too big or too small.

We have grown over 60% in the last 4 years and are continuing to open new locations across the US. Our formula for success is simple: consistent quality, a focus on safety, exceptional customer service—at the best price possible. Learn why we’re the right choice to service your industrial roofing system.

What makes us better?

We know you have a choice. Here’s how Nations Roof® stands out from the crowd by providing excellent work for our clients.

Quality

Our work speaks for itself. Our teams of commercial roofing contractors consist of highly trained roof maintenance specialists and our partnerships with leading manufacturers means that we install the best roofing systems available.

Customer Service

Our employees are committed to customer service, from our teams on the roof to executive management and everyone in-between. We are listening to our customers, driving our commitment to best in class customer service to ensure your commercial buildings remain in excellent condition.

Project Management

From pre-planning and project kick-off to completed job and project close out—our team works with yours on every detail. Working together is critical for mutual success, especially during a commercial roof replacement.

Technology

Our client portal, NationsFM, is a cost effective option that gives you access to the roofing system photos and data you need, when you need it and from any device. Managing your roof assets and other services have never been so easy.

Safety

Nations Roof® recently invested over $2 million dollars in new safety equipment and was awarded the 2017 NU’s Excellence in Workers’ Compensation Risk Management Award – a testament of our commitment to safety for every commercial roofing contractor we employ.

Trust Nations Roof®

Call today to schedule your 21 point, no obligation commercial roof inspection 678-718-4292

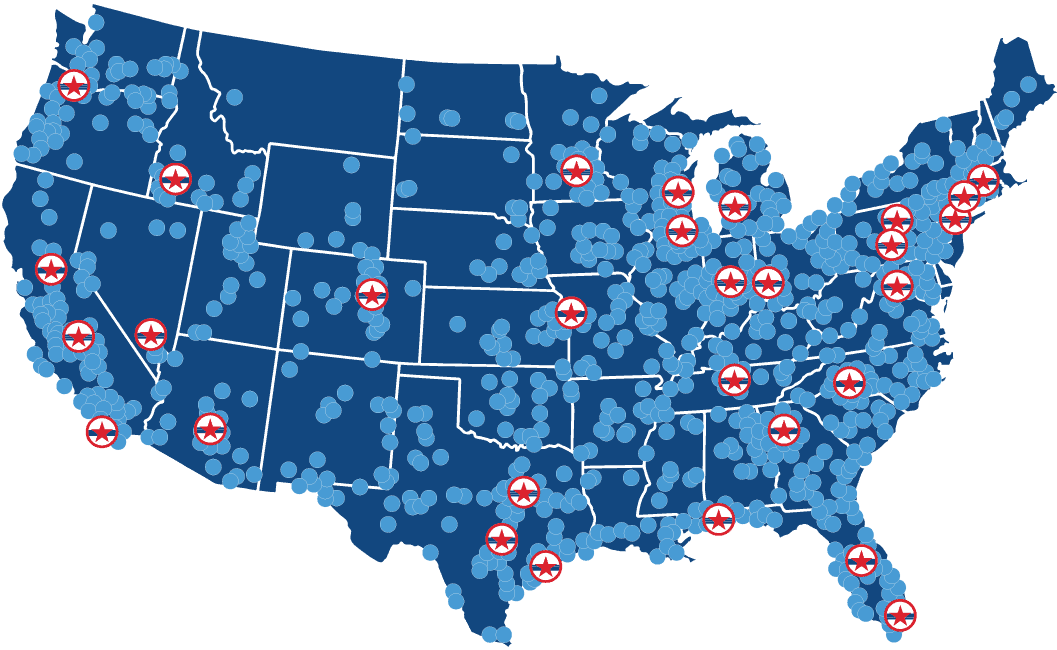

Our Locations

Areas we serve

We have twenty-eight locations in twenty-four states and are continuing our expansion across the US.

Our Work

VIEW OUR PORTFOLIO

Check out photos of completed industrial roofing projects—the chances are we’ve done a job with roofing problems similar to yours.

Call 678-718-4292

or

Schedule Inspection

Emergency

First Response

When disaster strikes your commercial building, you need a quick

response. Nations Roof® emergency response teams are ready

to mobilize 24/7, 365 days a year.

678-718-4292

Latest News

Nations Roof Recognized as a 2024 GAF Commercial Chairman’s Circle Award Winner

Quakertown, PA – March 2024 [...]

Nations Roof Named Winner of NRCA Gold Circle Award

February 8 – Nations Roof [...]

Nations Roof Appoints Rich Nugent as Chairman of the Board and Jake Hyatt as CEO

Rich Nugent has become Chairman of the Board and [...]